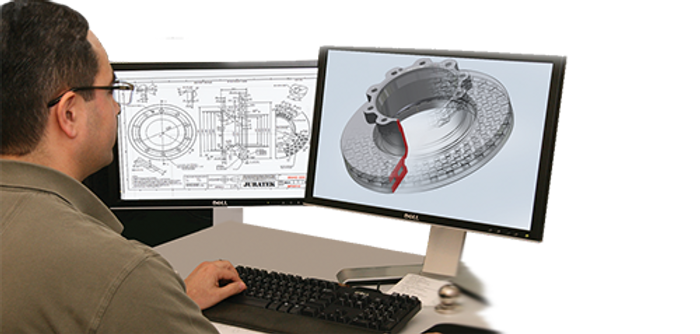

Juratek employs a team of professional engineers who have developed the products to today’s industry leading standards.

Using the latest Computer aided design software 3D models are produced based on measurements taken from our coordinate measuring machine (CMM). These models are then converted into 2D manufacturing drawings.

These models are also used in the routine inspection of the products once manufactured, to ensure conformity to the original design.

passenger cars

& lcv braking

Juratek have been supplying the automotive industry for over 25 years with the highest quality braking components.

The design and production of our brake discs and drums is controlled by our own engineers and every batch received is fully checked on our precision measuring machine.

All pads and shoes, are approved to UN ECE R90:02 regulations. But we take our quality testing much further, by using the OE industry designed tests SAE2521 & SAE2522

with all our products matching the OE design, Juratek are truly a Genuine Alternative...

Juratek employs a team of professional engineers who have developed the products to today’s industry leading standards. Using the latest Computer aided design software 3D models are produced based on measurements taken from our coordinate measuring machine (CMM). These models are then converted into 2D manufacturing drawings. These models are also used in the routine inspection of the products once manufactured, to ensure conformity to the original design.

Coated Brake Discs: Anti Corrosion paint is applied to the non-braking surface of all brake discs across

the range.

Cosmetic Protection: As many modern cars are fitted with alloy wheels, a rusty brake disc can be quite unsightly. However the coated brake discs, which can be seen

through the alloy wheels remains

a pleasant silver colour.

Vent Protection: The silver coating is also applied to the edge of the brake discs and inside the vent gap. This means that corrosion will not weaken the internal structure of the brake disc.

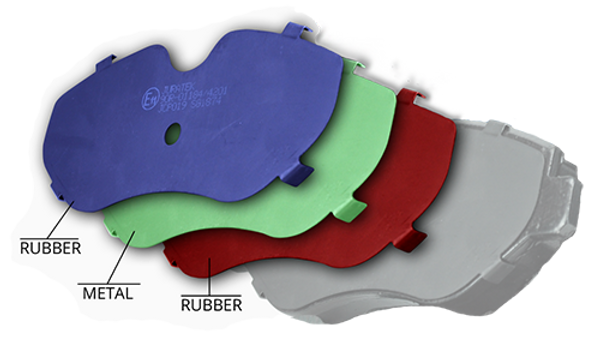

Initial Performance Strip

The Initial Performance Strip is added to all front application brake pads. This strip improves the performance of the brakes during the initial running-in period

As you can see the addition of the Green Stripe to the pad surface gives more friction, hence better braking, from the very first stop, in comparison with the same grade of pad material without the Green Stripe.

SAE2521 (AK Noise)

The effectiveness of our premium anti–noise brake shims is assured by tests we carry out to SAE2521 – the test developed by the OEM automotive industry to measure the noise performance of a vehicle braking system.

The test is carried out on a test rig comprising a full vehicle corner and is contained in an anechoic (sound-proof) chamber to prevent external noise pollution.

All Juratek brake pads are ECE R90 approved for fitting in any European country. The aim of ECE R90 is to establish a common minimum standard of braking performance, product integrity and manufactured quality for replacement brake linings across the whole of Europe. Previously, the market was unregulated and products of dubious performance and quality could be sold with impunity with consequent safety risks to all road users.

SAE2522 (AK Master)

This test programme used by the OEM brake industry to measure and develop brake pads for OE use and assesses their performance at the more extreme values of braking performance not covered by the ECE R90 test regime.

SAE2521 (AK Noise)

The effectiveness of our premium anti–noise brake shims is assured by tests we carry out

to SAE2521 – the test developed by the OEM automotive industry to measure the noise performance of a vehicle braking system.

The test is carried out on a test rig comprising a full vehicle corner

and is contained in an anechoic (sound-proof) chamber to prevent external noise pollution.

Initial Performance Strip

The Initial Performance Strip is added to all front application brake pads. This strip improves the performance of the brakes during the initial

running-in period

As you can see the addition of the Green Stripe to the pad surface gives

more friction, hence better braking, from the very first stop, in comparison

with the same grade of pad material without the Green Stripe.

brake pads & shoes

All Juratek brake pads are ECE R90 approved for fitting in any European country. The aim of ECE R90

is to establish a common minimum standard of braking performance, product integrity

and manufactured quality for replacement brake linings across the whole of

Europe. Previously, the market was unregulated and products of

dubious performance and quality could be sold with impunity with

consequent safety risks to all road users.

With fixed calipers, the entire caliper is solidly mounted to the axle or frame and there is a piston or pistons on both sides of the caliper. The pistons push the two brake pads onto both sides of the disc and therefore not require sliding pins to function.

The fixed caliper can apply more power and apply that power more evenly during braking. They also provide a better feel through the brake pedal whenever the driver applies the brake which is preferable for luxury and performance vehicles.

The complete caliper assembly comprises two structural parts – a caliper bracket which is solidly mounted to the axle of the vehicle and the caliper body which houses the hydraulic pistons.

The inboard element of the caliper body contains the pistons and the hydraulic pressure created from the brake pedal via the master cylinder initiates the direct

clamp of the piston side brake pad and the resulting

reaction force on the outboard side of the caliper clamps the outboard side brake pad to the disc. The caliper can slide either on pins contained within bushes or on the caliper bracket itself.

All Juratek brake calipers are approved for fitting in any European country under BER Regulation (EC) 461/2010. These calipers are 100% new calipers, so no old core or surchages need to apply.

100% Quality Testing

One of the most important tests is the high and low pressure test.

Each caliper will firstly be low pressure tested with a 0.6MPA pressure which lasts for 5 seconds, then a high pressure test is done under 4MPA which also lasts 5 seconds. If there is no pressure loss, then the product is approved for sale.

Brake calipers convert the braking effort applied by the driver to the brake pedal into a clamping force between the brake pads and brake disc at the road wheel.

There are two basic types of brake caliper in use:

All Juratek brake calipers are approved for fitting in any European country under

BER Regulation (EC) 461/2010. These calipers are 100% new calipers,

so no old core or surcharges need to apply.

100% Quality Testing

One of the most important tests is the high and low

pressure test.

Each caliper will firstly be low pressure tested with a 0.6MPA

pressure which lasts for 5 seconds, then a high pressure test

is done under 4MPA which also lasts 5 seconds. If there is no

pressure loss, then the product is approved for sale.

Brake calipers convert the braking effort applied by the driver to the brake pedal into a clamping force between the brake pads and brake disc at the road wheel.

There are two basic types of brake caliper in use:

Sliding Calipers

(also known as Floating or Fist Type calipers)

The complete caliper assembly comprises two structural parts – a caliper bracket which is solidly mounted to the axle of the vehicle and the caliper body which houses the

hydraulic pistons.

The inboard element of the caliper body contains the pistons and the hydraulic pressure created from the brake pedal via the master cylinder initiates the direct clamp of the piston side brake pad and the resulting reaction force on the

outboard side of the caliper clamps the outboard side

brake pad to the disc. The caliper can slide either on

pins contained within bushes or on the caliper bracket

itself.

Handbrake Calipers

Some floating calipers can also be used to operate the parking brake.

These can be either mechanically or electronically operated.

Mechanically Operated

This type of caliper is used for normal pedal braking and the piston is operated hydraulically. However it is also used to operate the parking brake.

If the floating caliper incorporates a parking brake, then it will have a brake lever which is connected to the parking brake by a brake cable.

When the parking brake lever is pulled force is applied mechanically instead of hydraulically.

Electrically Operated

This type of caliper is also used for normal pedal braking and the piston is operated hydraulically. However it is also used to operate the parking brake.

If the floating caliper incorporates an electronic parking brake, then it will have an EPB (Electronic Parking Brake) actuator fitted. The EPB (Electronic Parking Brake) unit contains an electric drive motor which via a spindle provides the actuation force to clamp the brake pads to the disc when the holding mechanism is activated by the driver via a switch or button.

The EPB is used as a part of a larger electronic brake control system which can provide safety functions such as automatic EPB engagement to prevent “roll away” in the event of an engine stall and “hill hold” to prevent the car rolling backwards.

calipers

.png)

With fixed calipers, the entire caliper is solidly mounted to the axle or frame

and there is a piston or pistons on both sides of the caliper. The pistons

push the two brake pads onto both sides of the disc and therefore

not require sliding pins to function.

The fixed caliper can apply more power and apply that power

more evenly during braking. They also provide a better feel through

the brake pedal whenever the driver applies the brake which is preferable for luxury and performance vehicles.

Fixed Calipers

hydraulics

All Juratek wheel cylinders are approved to ISO9001:2015, IATF16949:2016, ISO14001:2015 and ISO45001:2018. The units are low pressure tested to ensure seal quality. Dust caps and seals are manufactured from age-resistant EPDM material and housings and pistons are anodized to provide corrosion and wear resistant surfaces with all units made in the EU.

Juratek brake hoses are tested to SAEJ1401 requirements, burst tests and volumetric expansion tests. All assemblies are pressure tested 3000-3600psi and approved to both ISO9001:2015 and ISO14001:2015. The testing is carried out from raw materials through to the final product and all units are made in the UK.